Our products and solutions have proven their worth in a wide range of industries.

Making things work

Our products and solutions have proven their worth in a wide range of industries.

Making things work

Our products and solutions have proven their worth in a wide range of industries.

Making things work

Satisfied customers are our motivation

You are in good company with an interface from Innoface.

More than 100 companies globally, from medium-sized companies to enterprise groups and a wide range of industries, already trust us. We have compiled some testimonials from reputable companies for you.

STRATEC designs, develops and produces plant automation solutions for highly regulated laboratory markets.

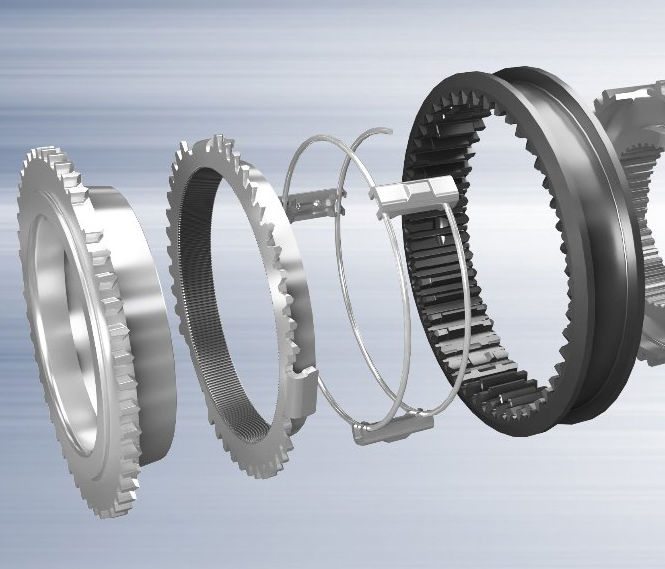

Oerlikon is a global innovation powerhouse for surface engineering, polymer processing and additive manufacturing.

HOERBIGER is active worldwide in the energy sector, the process industry, automotive industry, mechanical engineering, safety technology, and the electrical industry.

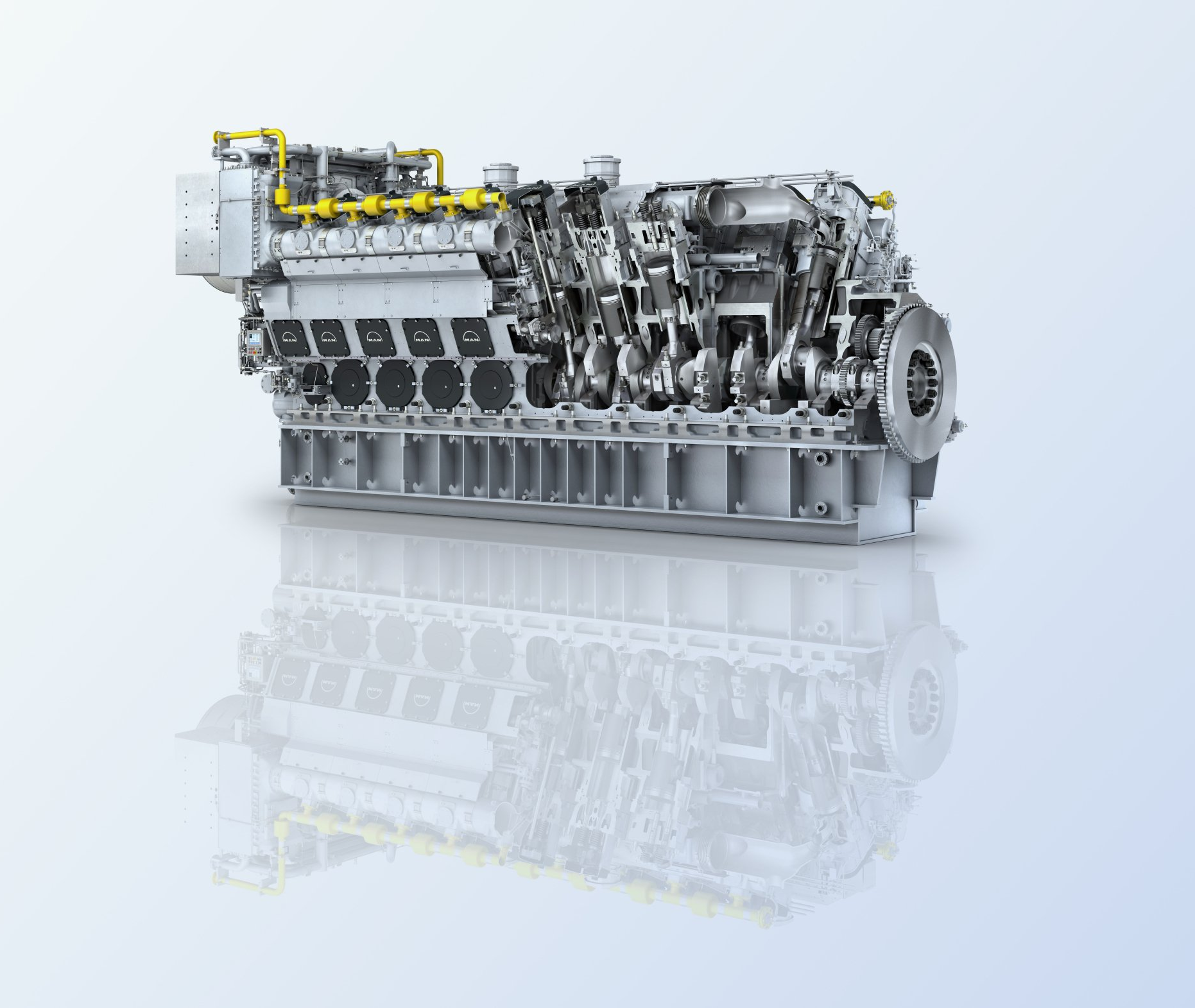

MAN Energy Solutions SE is a supplier of large diesel engines and turbo machines for marine and stationary applications.

The Neutrik Group develops, designs and manufactures innovative electrical and electronic interconnect products, power distribution systems, grounding systems and equipment for the digitization of electrical signals.

RONDO is one of the world's leading suppliers of machines and systems for the production of dough bands and their processing into dough pieces for croissants, bread, donuts and more.

Would you like more information?

"

Customer voices

“Only with the introduction of the IFConneX interface could STRATEC reach the level of material master and document creation it is operating at now. It was an essential criterion for the decision to introduce the Innoface interface."

Martin Hein, Head of R&D Applications, stratec

"

No suitable references for you?

We will be happy to provide you with further references upon your request!

@Innoface AG 2024

Locations

Innoface AG

Steinhäuserstr. 20

76135 Karlsruhe

Germany

Tel.: +49 721 6268730

Mail: support@innoface.de

INNOFACE AMERICAS INC

3505 Lake Lynda Drive

Suite 200

Orlando, Florida 32817

Tel.: +1 407 567 2500

Mail: support@innoface.com

Locations

Innoface AG

Steinhäuserstr. 20

76135 Karlsruhe

Germany

Tel.: +49 721 6268730

Mail: support@innoface.de

INNOFACE AMERICAS INC

3505 Lake Lynda Drive

Suite 200

Orlando, Florida 32817

Tel.: +1 407 567 2500

Mail: support@innoface.com