High-quality and consistent master data in all systems, reduced maintenance effort and transparent lifecycle status.

Making things work

High-quality and consistent master data in all systems, reduced maintenance effort and transparent lifecycle status.

Making things work

High-quality and consistent master data in all systems, reduced maintenance effort and transparent lifecycle status.

Making things work

RONDO

Reference summary report

Initial situation

- There was no existing coupling between the Windchill and SAP systems.

- The transfer of product data such as material master, bill of materials and documents was done completely manual.

- Change operations were only executable with manual steps.

- The drawings were not available in SAP.

- Due to the manual transfer, the material master data in PTC Windchill and SAP were inconsistent.

- The lifecycle status in Windchill and SAP was not always synchronized.

Customer requirements

- Automated interface transfer as well as quality improvement of the important master data, BOM and documents for more consistency.

- Transparent lifecycle status in both systems

- Clean cross-system change workflow

- Minimization of waiting times and efforts in master data maintenance as well as optimization of revisioning.

- Support of Windchill MPMLink functionalities

- Compatibility with SAP S/4Hana Public Cloud

- Released drawings and documents should be available in SAP and Windchill so that employees can find them in both systems without duplicates or incorrect revisions.

- Standardized and system-oriented processes

Implementation

- The interface allows the automatic creation or modification of material masters, document info sets and bills of material.

- The transfer is process-driven from the change notice workflow and promotion request workflow.

- If required, master data maintenance from Windchill to SAP can also be controlled or triggered via menu.

- All data is validated before transmission so that a minimal level of quality is ensured.

- The processes are standardized for all users.

- The system sovereignty with regard to parts data, parts lists and product-describing documents lies with the Windchill product management system.

Customer benefits

- Thanks to the introduced validations and the user-friendly operation of the interface, the number of people who can transfer materials to SAP has been increased, thus minimizing waiting times and effort.

- This reduced the need for key user support.

- Various validations detect errors even before a material is transferred to SAP.

- The interface's own error messages, which are more detailed than the messages generated by SAP, contribute to a better understanding by users.

Initial situation

- The transfer of product data such as material master, bill of materials and documents was done completely manual.

- Change operations were only executable with manual steps.

- The existing coupling between the Windchill and SAP systems could only partially cover the requirements.

- The material master creation through the interface was incomplete which created a lot of additional work.

- The drawings were not available in SAP.

- Due to the manual transfer, the material master data in PTC Windchill and SAP were inconsistent.

- The lifecycle status in Windchill and SAP was not always synchronized.

Customer requirements

- Automated interface transfer as well as quality improvement of the important master data, BOM and documents for more consistency.

- Transparent lifecycle status in both systems

- Clean cross-system change workflow

- Minimization of waiting times and efforts in master data maintenance as well as optimization of revisioning.

- Support of Windchill MPMLink functionalities

- Compatibility with SAP S/4Hana Public Cloud

- Released drawings and documents should be available in SAP and Windchill so that employees can find them in both systems without duplicates or incorrect revisions.

- Standardized and system-oriented processes

Implementation

- The interface allows the automatic creation or modification of material masters, document info sets and bills of material.

- The transfer is process-driven from the change notice workflow and promotion request workflow.

- If required, master data maintenance from Windchill to SAP can also be controlled or triggered via menu.

- All data is validated before transmission so that a minimal level of quality is ensured.

- The processes are standardized for all users.

- The system sovereignty with regard to parts data, parts lists and product-describing documents lies with the Windchill product management system.

Customer benefits

- Thanks to the introduced validations and the user-friendly operation of the interface, the number of people who can transfer materials to SAP has been increased, thus minimizing waiting times and effort.

- This reduced the need for key user support.

- Various validations detect errors even before a material is transferred to SAP.

- The interface's own error messages, which are more detailed than the messages generated by SAP, contribute to a better understanding by users.

CUSTOMER FEEDBACK

Marc Besson,

Chief Technical Officer

„Our three backbone systems PLM Windchill, SAP ERP and Dynamics 365 require accurate, well-maintained and redundant master data. This is the basis for successful production, digitization and lifecycle management. The three systems only unfold their full functionality and performance with the introduction of the IFConneX interface. Without this high-performance interface, collaboration between interdisciplinary teams at different locations would hardly be possible anymore, as manual data entry in multiple systems is too slow and too prone to errors.“

Customer Feedback

Marc Besson,

Chief Technical Officer

„Our three backbone systems PLM Windchill, SAP ERP and Dynamics 365 require accurate, well-maintained and redundant master data. This is the basis for successful production, digitization and lifecycle management. The three systems only unfold their full functionality and performance with the introduction of the IFConneX interface. Without this high-performance interface, collaboration between interdisciplinary teams at different locations would hardly be possible anymore, as manual data entry in multiple systems is too slow and too prone to errors.“

About RONDO

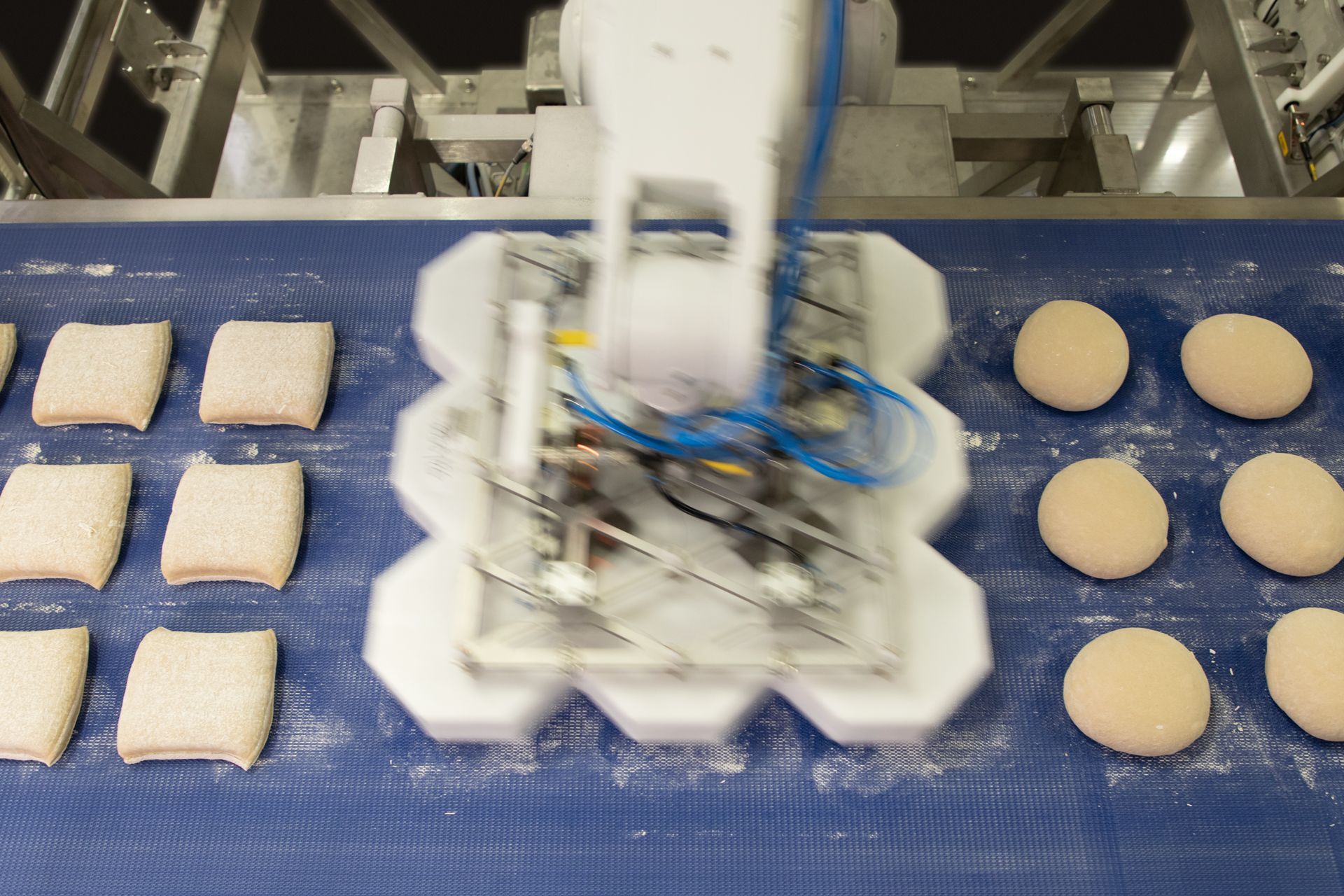

The Swiss company RONDO was founded in 1948 and has since become a leading global supplier of machines and systems for the production of dough bands and their processing into dough pieces for croissants, pastries, bread and rolls, pizzas, and donuts. Their customers include companies of all sizes - from small artisan bakeries to industrial manufacturers.

Dough-how

All machines, lines and equipment are based on the so-called Dough-how, "the unique combination of expertise and experience in dough and technology".

In 1953, RONDO invented and patented the world's first dough sheeter. Today, the company is still the industry's innovation leader. The RONDO Group employs around 430 people at its headquarters in Burgdorf and in ten subsidiaries and sales offices in Europe, the USA and Asia.

Photo credit: ©RONDO Burgdorf AG | www.rondo-online.com

About RONDO

The Swiss company RONDO was founded in 1948 and has since become a leading global supplier of machines and systems for the production of dough bands and their processing into dough pieces for croissants, pastries, bread and rolls, pizzas, and donuts. Their customers include companies of all sizes - from small artisan bakeries to industrial manufacturers.

Dough-how

All machines, lines and equipment are based on the so-called Dough-how, "the unique combination of expertise and experience in dough and technology".

In 1953, RONDO invented and patented the world's first dough sheeter. Today, the company is still the industry's innovation leader. The RONDO Group employs around 430 people at its headquarters in Burgdorf and in ten subsidiaries and sales offices in Europe, the USA and Asia.

Photo credit: ©RONDO Burgdorf AG

@Innoface AG 2024

Locations

Innoface AG

Steinhäuserstr. 20

76135 Karlsruhe

Germany

Tel.: +49 721 6268730

Mail: support@innoface.de

INNOFACE AMERICAS INC

3505 Lake Lynda Drive

Suite 200

Orlando, Florida 32817

Tel.: +1 407 567 2500

Mail: support@innoface.com

Locations

Innoface AG

Steinhäuserstr. 20

76135 Karlsruhe

Germany

Tel.: +49 721 6268730

Mail: support@innoface.de

INNOFACE AMERICAS INC

3505 Lake Lynda Drive

Suite 200

Orlando, Florida 32817

Tel.: +1 407 567 2500

Mail: support@innoface.com